Welcome to Our Blog

Hydraulic Training, Troubleshooting & Reliability

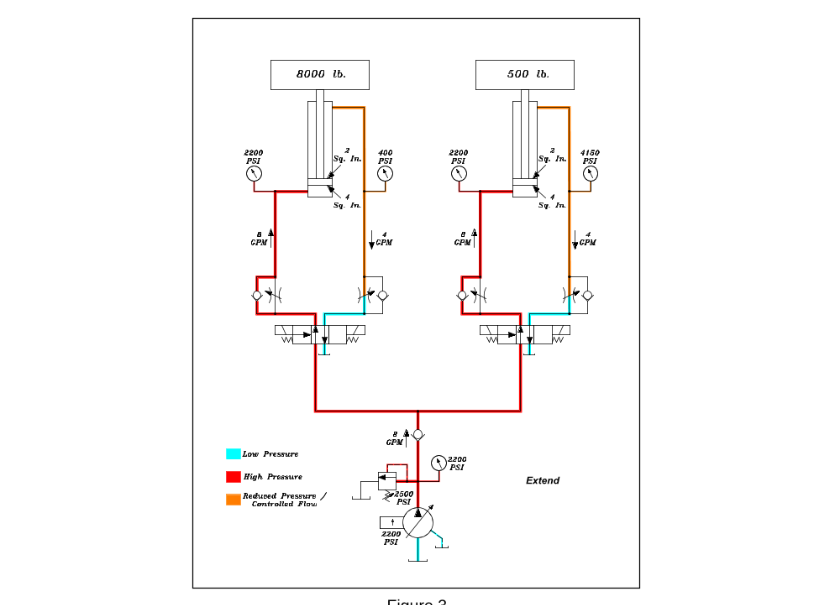

Meter Out Flow Controls and Pressure Intensification in a Hydraulic Cylinder

There is a common misconception that the pressure in a hydraulic system using a pressure compensating pump is limited to the pump compensator setting. However, the compensator setting merely determines the pressure at the outlet of the pump itself. Many people do not realize that the pressure at different ports in the system can be much higher than the pump compensator setting. This is due to several factors, one of which is the pressure intensification in a hydraulic cylinder when using meter out flow controls.

Air Receivers – Function, Sizing and Testing

Selecting the correct size for an air receiver can reduce excessive cycling of the compressor as well as limit the current draw of the electric drive motor. In many applications, both primary and secondary air receivers are used to provide additional air to the system. Automatic or manual drain valves and relief valves should always be installed with any receiver.

5 Tips on How to Increase the Reliability of Your Hydraulic Systems

When most people think of preventive maintenance and reliability procedures for a hydraulic system, regularly changing filters and checking the oil level are the only things considered. When the machine fails, there is often very little information about the system to refer to when troubleshooting. However, proper reliability checks should be done with the system running under normal operating conditions. These checks are vital for preventing equipment failures and downtime.

What is a Lubricator? Why do I Need One?

Leakage control, filtration, and lubrication are three of the greatest challenges in keeping a reliable pneumatic system. In this post we explain one of the least understood of the three, the air lubricator – how it works, why it is needed, how to properly adjust it.

Don’t Ignore Hydraulic Pipe Size!

Most machines get modified at some point, usually either to make them run faster, or to increase their functionality. Usually, this requires additional flow. Can all of the existing pipes, tubing, and hoses meet the new demands? Often, they are overlooked when changes are made.

Basic Hydraulic Troubleshooting Workshop Grande Prairie Alberta April 7-9

Our 3-Day Basic Hydraulic Troubleshooting workshop will be conducted in Grande Prairie, Alberta April 7th – 9th, 2020. Call (770) 267-3787 or email gpm@gpmhydraulic.com to register.