Welcome to Our Blog

Hydraulic Training, Troubleshooting & Reliability

Outdoor Hydraulic/Pneumatic Classes

Our best protections against the Coronavirus are to keep our face covered, keep our hands clean, keep our distance, and if we leave home be outdoors breathing fresh air. For the duration of the pandemic, we will provide an outdoor solution to conduct the expert training you need, either a pavilion at a nearby park or an event pavilion tent erected in the parking lot or lawn of your plant.

Hydraulic Classes Rescheduled Due to Virus

Since many of our students are unable to attend due to the Corona virus shelter-in-place order as well as company directives by their employers, we have rescheduled three of our 3-Day Basic Hydraulic Troubleshooting workshops so that we may accommodate as many students as possible. Other classes may well be rescheduled as well for the same reasons, but we will make every effort to alert you as soon as possible.

The three classes currently affected are:

Basic Hydraulic Troubleshooting Roanoke Rapids, North Carolina. originally scheduled for June 16th – 18th will now be conducted September 22nd – 24th, 2020.

Basic Hydraulic Troubleshooting Grenada,Mississippi, originally scheduled for May 19th – 21st will now be conducted August 25th – 27th. 2020.

Basic Hydraulic Troubleshooting Salem, Oregon originally scheduled for June 2nd – 4th will now be conducted September 22nd – 24th, 2020.

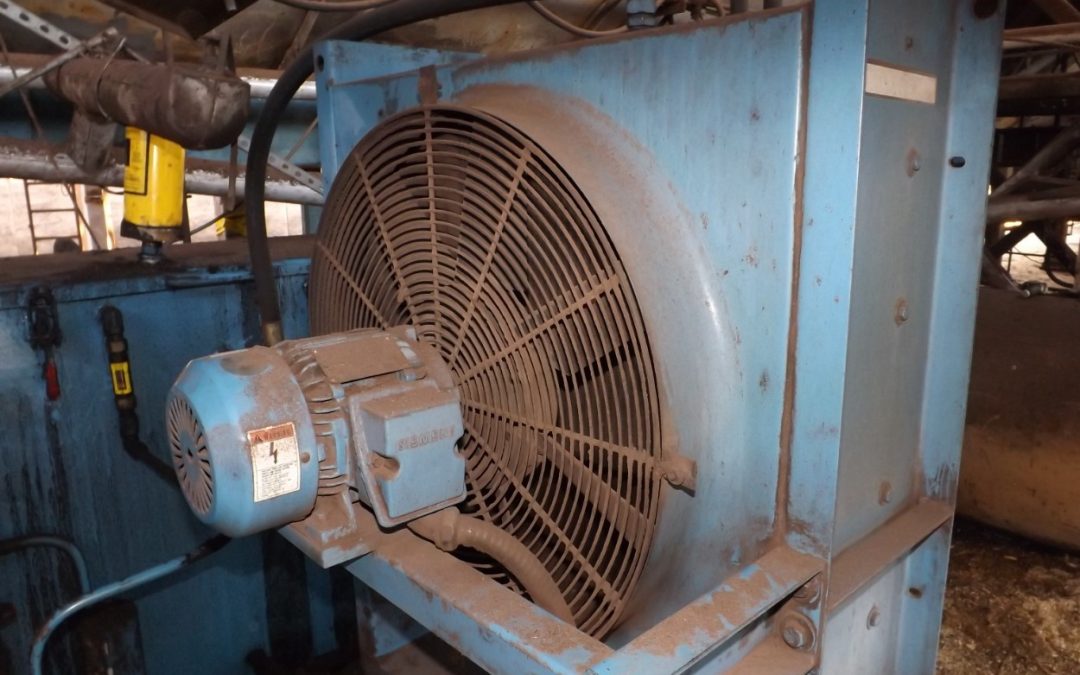

How to Choose the Right Heat Exchanger Type and Location for Your Hydraulic System

Excessive heat can affect a hydraulic system in many ways. Generally, oil temperatures in excess of 140°F (60°C) will cause the oil to rapidly degrade. Other effects include accelerated wear of system components and damage to bearings and seals. Therefore, high oil temperature is a major concern. A properly sized and located heat exchanger in a hydraulic system can save time, money, and repair headaches. Most importantly, system downtime will be greatly reduced.

Starting Back Up

As our nation, and the whole world seek to restart after the COVID-19 crisis, it is important that care is taken when restarting hydraulic machinery that you do not cause more harm than good. When hydraulics sit for weeks at a time, special precautions must be taken for a safe and effective startup. Throughout this article we will discuss certain procedures and checks that should be done for a more effective startup.

Receptores de Aire: Función, Dimensionamiento y Prueba

Seleccionar el tamaño correcto para un receptor de aire puede reducir el ciclo excesivo del compresor y limitar el consumo de corriente del motor de accionamiento eléctrico. En muchas aplicaciones, se utilizan receptores de aire primario y secundario para proporcionar aire adicional al sistema. Las válvulas de drenaje automáticas o manuales y las válvulas de alivio siempre deben instalarse con cualquier receptor.

The Most Common Mistakes Made by Untrained Hydraulic Technicians

When servicing and troubleshooting hydraulic equipment, we all make mistakes. After all, we are human. These mistakes can cost us in many ways and almost always result from a lack of competent training. Working around hydraulic machines can be a complex exercise, as it involves a great deal of science. To avoid these common mistakes, a logical approach based on knowledge (including knowing the function of each hydraulic component) and sound troubleshooting principles is required.